2004-05-17

Added some more pictures and data plots in the Uncooled Chamber Tests section.

2004-04-24

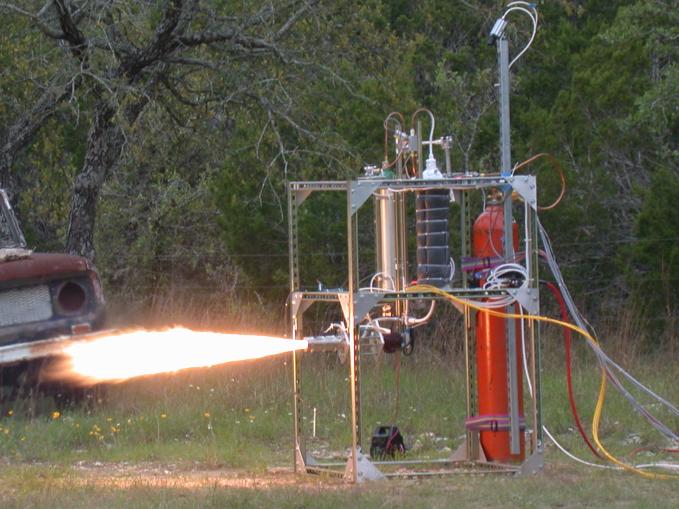

Finally ran the live fire test on 2004-04-18. You can find the

pictures and mpegs in the

Uncooled Chamber Tests section. Everything worked as

expected for the most part. I was prepared for the worst but

hoping for the best! There were two runs of 6 seconds each.

The combustion chamber was in good shape - no visible erosion of

the walls. In fact, you could still see the machine marks on the

walls of the chamber. The outside turned dark blue about two inches

downstream from the injector which corresponds to a temperature of

between 550 and 600 degF. The inside was covered in soot from the

kerosene combustion so with what I now know about the

insulating effect of kerosene deposits on the chamber walls, it

makes sense that there wasn't any erosion on such a short run.

For some reason, I didn't get useful information

from my surface-mounted thermocouples on the outside

of the chamber. The temperature rose as expected but the

thermocouples only registered a maximum of about 280 degF so I

have some investigation to do. I'm hoping I can back out the heat

flux through the wall since that's an important design parameter for the regen engine.

The plots from run 1 and run 2 show all the sensor data that was

acquired.

The thrust was about 80 lbf for Run 1 and about 90 lbf for Run 2.

I think these differences from the design of 100 lbf are due to

inadequate delivery of propellant to the injector. As you can see

in the plots, the tank pressures started dropping once the test

started. The thrust appears to be low by the same percentage as

the tank pressures (supposed to be 280 psig). Since I didn't see

this with my water testing, the only thing I can think of is

either the LOX absorbed a lot of the N2 or I didn't crack the

valve open enough on the N2 bottle used for pressurization. I

plan to repeat the test with water to see if the valve not being

open enough may have contributed to the drop in tank pressure. If

you scale the thrust by the amount that the tank pressures were

low, the thrust would have been right on target.

Filling the propellant tanks was uneventful - I was paranoid

about transferring the LOX and keeping the lines clean so I guess that

paid off. Other than that, the most dangerous part was

transporting the LOX dewar in the trailer out to the test site.

Another interesting artifact in the data is the startup

transient in the chamber pressure and thrust. I intentionally

turned the fuel on first and followed with the LOX about a half

second later. This was based on advice that you want to start and

end with a rich mixture. The thrust went up to about 50 lbf initially,

then dropped down to 35 lbf before ramping back up to 90 lbf. My

theory is that the fuel initially reacted with the existing GOX in

the chamber. Since the LOX hadn't arrived yet, the mixture became

very rich (notice the black soot in the videos). A short time

later, the LOX valve fully opened and the thrust started back up

again. Next time, I won't get so fancy with the sequencing and

just start them at the same time. Since the ignitor shot out (by

design) during the startup transient, there was a risk that by the

time the LOX arrived, the combustion would have already stopped,

leading to a buildup of LOX in the chamber, etc.

For the ignitor, I just ended up using a auto ignition coil

connected to a relay configured to buzz the contacts and generate

pulses. I was able to get about a 1-1.5 inch spark from this

setup. Since I didn't want the high voltage wire and/or the

ground wire touching the walls of the chamber and shorting out, I

made a little 0.25 x 0.5 x 0.25 inch plastic insulator block that

I ran the exposed end of the wires through. Then, I just inserted

the assembly up into the chamber about two inches from the

injector. I didn't want the injector blowing out prematurely so I

loosely attached the wires with a cable tie to a fastener in an

extra set of holes near the nozzle exit.

The noise from the firing was plenty loud - louder than I

expected. It all happened so fast that I didn't really know

whether it was going to work or blow into pieces! The startup

transient had me wondering whether it had fizzled out but when it

started going full blast, it was really cool! It's really hard to

describe the feeling I had after the run - I felt this strange

urge to do it again! So, we waited an hour or so for things to

cool down and ran it again. I think I'm hooked.

By the way, special thanks to Mike for providing an awesome

test site and to Reed for not only helping out over the past few

years but getting the equipment to the test site.

So what's next? Now that the test stand hardware and software

has been checked out and I've figured out how to safely handle

LOX, it's time to move on to the regen engine. The plan is to

work on three approaches simultaneously - an

aluminum motor with cross-drilled holes, a spun copper

motor with a spiral wrapped tube brazed to the outside, and a

graphite nozzle connected to a tubular chamber with an annular

cooling jacket. The easiest one to manufacture that meets the

requirements will be the one to go with. The ultimate goal is for

a real flying rocket so even after all this work, I've really only

taken a small step toward that goal. Sometimes it's hard to stay

motivated with a home project, especially one that took three

years but occasional successes really help!

2004-04-18

It worked! It's been a long day so stay tuned for all the fun details.

2004-01-26

I've been busy rebuilding the test setup over the past few weeks

and getting ready for the tests with LN2 and water. I had been

using tap water for the tests which left a lot of junk behind in

the tanks, tubing, and valves. Also, the wet locations where I had

brass fittings into aluminum got bit by galvanic corrosion. The

dry areas in the pressurization lines seem to be ok with brass

fittings. Just to be safe, I switched over to stainless fittings

in the areas where I'm using water for testing. I've also become

real careful about cleanliness and using started using only

distilled water for the tests. I don't feel like taking the ball

valves apart again.

Ran tests with cold water and LN2 this weekend. Turns out it was

a great idea to run with LN2 before trying with LOX for real as I

uncovered a few showstopper problems with my setup that didn't

show up with water testing:

-

The LOX ball valve is harder to turn at low temps than I

expected so I'll need a bigger air actuator to get more torque on

the handle.

-

Residual water in the tank and ball valve generates ice when

mixed with LN2 which in turn clogs up the injector holes.

It was harder than I thought to get all the water out. I ended up

using a heat gun on the aluminum tank, valves, and tubing, along

with a lot of dry N2.

-

Filling the tank through the the vent port on the top ices up

the internal threads so I can't put the burst disk holder back onto the

tank. So, I drilled and tapped a separate hole for a fitting near

the top of the tank just for filling. Since the tube fitting has

external threads on the top, I can easily attach and detach the

fill hose and plug.

-

Cracking the LOX ball valve open a slight amount while

filling the tank keeps dry gas flowing through the injector holes.

This in turn keeps any water vapor in the injector holes from

turning to ice. The humidity was near 100% and raining the past couple of

days so in a way, I'm glad I ran into these problems now instead

of during the test.

-

I'll need to insulate the LOX tank because all the liquid

(~1.5 gal) boiled off within about 5 minutes or so. I'm not sure

that's enough time to get everything buttoned down and back to the

test control area after filling the tank.

-

Other misc. electronic problems with the test setup - I was

getting random dropouts of the watchdog timer which in turn shuts

everything down. In general, there are some EMI problems I need

to work out, starting with putting diodes across the solenoids.

Also, the LOX tank pressure transducer has been acting flaky so I

need to swap it out - it may have been damaged by the low cryo

temps. Although it didn't see the LN2 directly, the whole

assembly was really cold.

See the Uncooled Chamber Tests

section for some cool photos.

|