10/11/07

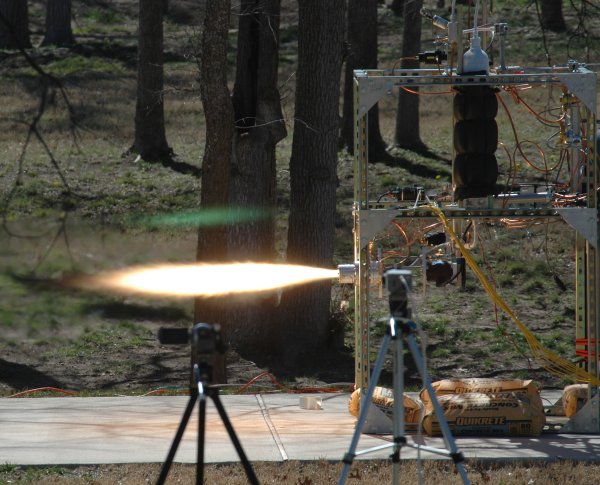

Well, I've achieved my first major goal of this project. I

ran my 100 lbf regen engine last weekend

with the new injector and got the expected performance out

of it. I only accomplished one run (see below) but it turns

out that was all I needed to finally validate the basic design.

Here's how the run stacked up:

-

Design thrust = 100 lbf, actual = 94

-

Design mixture ratio = 1.8, actual = 1.79

-

Design chamber pressure = 190 psia, actual = 182

-

Design propellant flow = 0.449 lbm/s, actual = 0.429

-

Design Cf = 1.31, expected = 1.29, actual = 1.22

-

Design Isp = 234, expected = 223 , actual = 220

-

Design c* = 5716 ft/s, expected = 5550, actual = 5749

I added another set of values to this table. The "design" values are what you

would get from Propep with the actual mixture ratio and chamber pressure,

while the expected values are what I calculated with typical

performance correction factors. The thrust was a bit low

but so were the tank pressures and associated propellant

mass flow. I only wish I had tried this "traditional" injector the

first time as it would have saved me over a year of testing and analysis. Putting a

positive spin on it, now I have a better understanding of hydraulic flip and

injector mixing! Both flowmeters worked as expected and I got flow rates close

to what I predicted based on pressure ratio.

The run lasted about 23 seconds and had a very clean shutdown. I think this

is the first time the computer was able to shut down the test normally

without running out of LOX first. As a result, there was no residual fuel

left in the chamber. As before, there was no visible erosion in the chamber

or injector face. The engine did get pretty hot though, much hotter than I

predicted. My back of the envelope calculation for gas-side heat transfer

coefficient came out about 2x of what I predicted. That caused the fuel to

heat up to about 475 degF, quite a bit more than the predicted value of 384

degF. I don't see any sharp changes in the wall temperatures so I don't think

I got any coking of the fuel. Maybe you wouldn't for a short-time run like

this. I haven't thought about it hard enough to decide whether the higher

temperatures were due to the injector spray pattern or the higher performance.

Remember that my original injector for this engine was specifically designed

to keep the spray away from the walls (but apparently it had poor performance).

When I took the engine apart, I got a bit of a surprise. My aluminum foil and

Grafoil gasket combination leaked between the injector face and one of the

cooling passages. I suspect it sealed itself up pretty quickly because there

was a bunch of soot and carbon in that area. The fuel would have still made it

into the chamber though. I would think that a sudden change in spray pattern

would show up in either the flame shape, chamber pressure, or wall temperatures

but you don't really see that. Well, there is something funky going on early on

with the temperatures and maybe that is what happened. I suppose it's possible

that all the fuel bypassed the last two "tubes" and sprayed directly into the

chamber sideways. That would cause the engine to get quite a bit hotter

than normal. I'll never know for sure but I may have crunched the gasket

sandwich when I assembled the engine. It doesn't really matter because next

time I'm going to use o-rings to seal instead of Grafoil.

I only got one run out of two days of testing because of several problems. On

the first day of testing (Saturday), I almost canceled the test because of

rain. After lunch, the sun popped out so I decided to give it a shot. Oh, by

the way, I got booted out of the homestead for testing because some grumpy

neighbors complained about the noise. Doesn't everybody appreciate rocket

testing? It's not like it was every weekend and the noise wasn't any worse

than the F-16s that routinely blast overhead. Anyway, by the time I dragged

all the equipment out to the alternate test site, set everything up, and fired

the engine, it was getting close to dark. I took off the LOX flex hose (for

cleaning) and headed home for the evening. The next day (Sunday), I got

everything set up and that's when the problems started. Before installing the

LOX flex hose, I bent it back and forth a bit in my hands to check it and I

noticed a funny sound. No, it couldn't be... I hooked it up to the tank and

subjected it to a low pressure leak test. Sure enough, it leaked like crazy -

my LOX flex hose had failed. I thought those things were bulletproof but maybe

I flexed it one time too many or violated the minimum bend radius. No

problem - I came with extra plumbing so I started to make a copper

replacement. The injector fitting needed to be changed out and that's when

things got a lot worse. I've been using stainless steel NPT fittings into

aluminum without any particular difficulty, as I was always careful to not

torque them too hard. Well, as soon as I started removing the old fitting, I

got that sick feeling as I noticed it not getting any easier to remove. The

fitting was stripped! It was getting late in the day and things were breaking

so I decided it was time to quit. It turns out that was a good decision

because when I disassembled the engine the next day, that's when I discovered

the failed gasket. I also lost some time troubleshooting a bad power strip

when the computers kept turning themselves off randomly.

Overall, I'm happy with where I am on the project, although I didn't think it

would take this long to get to this point. As stated in my original project

goals, it's time to move on and build a rocket so I can run this engine

somewhere else besides the ground. I'm going to start by adding up expected

weights of all the parts to see if this size engine will work or if I need to

go to larger engine like 200-250 lbf. There's still some unanswered questions

about the higher temperatures I saw on this last run but that's something to

work out the next engine. Stay tuned!

2007-07-04

Created a new section for Software and

placed a current copy of my test stand control program up there.

I ran water tests with the new injector last weekend. The impingement

looked very good with no significant misalignment. Photos will be posted

shortly.

2007-05-29

Completed the

new injector with the traditional unlike impinging elements this weekend.

Everything turned out great except for the last cut I made (it always

works out that way doesn't it?) I mis-calculated the radius for the face

seal o-ring groove and cut it with too small of a diameter. It might still

work as-is but I'll know for sure when I do the cold

water tests. At the worst, I'll just have to make a new

injector cap which is a pretty simple part. This new injector

has an L/d of about 7 for the orifices so hopefully I won't see any problems

with hydraulic flip. A cleanup cut on the LOX inlets should have taken

care of any inlet burrs. There will still be a sharp edge but I have

some sanding cord that might help. Finally, I have new parts for the LOX flowmeter

but I need to convince myself the downstream flow straightener will actually

stay in the flowmeter before I put it back in service. I got lucky last time

when the flowmeter parts started heading toward the engine but didn't have

a disaster.

Next up are some minor mods to the test stand to allow easier and safer

LOX loading. I estimate the next test will take place in about 1-1.5 months.

2007-05-05

Finally got around to doing the

heat transfer analysis from all regen test results. Bear in mind that

these tests took place over the span of a year and there were some questionable

flow measurements but nevertheless, the data follows a trend. Unfortunately,

it follows a trend exactly backwards of what you would expect. Since my

LOX/kerosene engine was designed fuel rich at a mixture ratio of 1.8, you would

expect temperatures and heat flux to go up as the mixture ratio leans out but

that's not what I see. I'm convinced now more than ever that my existing

injector is causing this trend along with the low thrust and chamber pressure.

Here's my thinking: since the stream is highly concentrated in the center, as

you add more LOX, it just increases the amount of external combustion. I need

to go ahead and fabricate a new injector with traditional unlike impinging

elements.

However, given the problems with the thrust and injector, some of the results

are a lot closer to the predictions that I expected. The "smoothest" run I had

over all these tests was the one at r=1.7 and that is the one that most closely

matches the predicted heat flux,

gas-side heat transfer coefficient, wall temperature, and

fuel temperature at the cooling jacket exit.

Since I'm suspecting incomplete combustion, for a reasonable comparison against test data,

I recomputed the predicted values using the actual chamber pressure, thrust, mixture ratio,

etc. from the test data. One interesting thing I found along the way was an error in my

formula for the surface area of the converging and diverging portions of the nozzle which

raised the predicted heat flux over what I originally designed.

The plot of

runtime vs. measured LOX flow is interesting because it tends to

point toward reasonable measurements from the LOX

flowmeter. The only run that doesn't follow the trend is 20070225-Run1 and that

is the one where I suspect some other issues going as the thrust and chamber pressure were

jumping around a bit. The runtime measurement is essentially a measure of how much LOX there

was in the tank because in all cases, I intentionally put more fuel in the tank that I would

possibly need. That keeps me away from the problem where you're spraying LOX on the hot chamber

walls because the fuel ran out too early. However, runtime as a direct measure of the LOX

flow isn't too valid because the LOX boils off pretty quickly after loading the tank and the

time from closing the tank to starting the test varied quite a bit from test to test. However,

the trend is reasonable in my opinion.

2007-04-24

Had an interesting weekend -

burned through the throat on the uncooled engine, had a

LOX flowmeter come apart

, and had some good runs on the regen

chamber.

I had planned on at least 3 runs of the uncooled engine - a couple to

zero in on the right mixture ratio and one with a chamber extension to try

a different L* to see if it helped with the low thrust and chamber pressure.

The first run of the uncooled engine went well but at the very end as I was

shutting things down, it sprayed out a

massive burst of sparks and I knew right away

that was the end of that engine. The outside of the engine

looks fine but the throat of the solid steel chamber just melted away. I'm

guessing that my manual termination of the test may have caused the problem.

Normally, I let the computer shut down the LOX about 0.5 seconds before the

fuel so no LOX hits the hot walls. But since I had the 30 second regen

sequence loaded, I figured I would just shut it down with the big red button

as I've done before on regen runs. I've recently changed out the fuel valve

to a real rotary ball valve instead of my homemade ball valve actuator and

it opens and closes a lot faster than the LOX valve. So, it probably sprayed

the throat with LOX. The regen engine has all the pressurized fuel in

the cooling passages that dribbles out after the valve closes so it keeps

things running until all the LOX is used up.

If you believe the flowmeters (see discussion below), the uncooled engine

was a perfect run for the mixture ratio. The design mixture ratio was 1.8

and I ran it at 1.83 so that looked good. The thrust was 80.5 lbf and the

chamber pressure was 172.5 psia, compared to the design of 100 lbf and 190

psia respectively. Note that I tweaked the expected design chamber

pressure from 200 psia down to 190 psia to match the as-built throat

diameter. With the apparent mixture ratio so close to the design, you can

imagine my disappointment when the throat burned through on the first run

because I was hoping to do some more runs on it.

Next up was a run of the 100 lbf regen engine. Based on the as-built

dimensions of the the engine, I adjusted my expectations for chamber

chamber from 200 psia down to 185 psia. Based on pressure vs. flow ratios

from the tests two months ago, I adjusted the tank pressures to what I

thought were appropriate values. However, during the test, instead of 7.5 in^3/s

of LOX, the flowmeter reported about 15 in^3/sec, double what it should

have been! If that value is indeed real, I ran the test at a mixture ratio

of 3.47 instead of the 1.8 I was hoping for. Propep reports a chamber

temperature of 6116 degR instead of the 5458 degR that I designed for. You

would think that would cause the chamber to get a lot hotter than I designed

for but it didn't. When I get a chance, I'll run the thermal analysis to

see what the difference in wall temperatures are. The thrust on this run

was about 62 lbf and the chamber pressure was 136 psia, the lowest I've had with

this engine.

I was convinced something was definitely wrong with the LOX flowmeter so

I loaded up the tank intending to just run some LOX through it to check the

flowmeter. Imagine my surprise when I got 0 on the flowmeter reading.

Hmmm, ok, try it again, maybe it was iced up or something. Same problem.

Took apart the flowmeter and found it empty inside! No rotor, no flow

straighteners, nothing. I found all the parts except for the spring, spacer,

and c-clip a few inches away right in front of the LOX ball valve.

Amazingly, all the high-value parts were intact and undamaged. Of course,

the missing spring and spacer made it impossible to use the flowmeter

again. They must have gone through the ball valve and out into the air as there

was no injector hooked up for this checkout. Things were breaking, and it was

getting late anyway so I decided to call it a day.

So here's my confusion - when I first installed the flowmeters, I ran

water tests with a bucket to check the calibrations. The

flow vs. pressure curves for both the fuel and LOX orifices looked good, the

flowmeters matched the timed bucket, and more importantly, the flow rates

matched theoretical values for the orifice geometry. After the

cold water tests, I ran LOX through the flowmeter and injector to make sure

I got the pressure drop across the orifices that I expected. However,

with LOX, the flowmeter reported about half of the expected flow, like the

Cd dropped down to 0.5.

The only things I can think of that might cause the Cd to be so much

lower with LOX vs. water are: 1) water/ice in the flowmeter bearings, 2) water/ice

in one or more of the injector orifices, or 3) cavitation in the flowmeter.

But here's the really strange part - on the last hot fire before the flowmeter

disintegrated, the flow rate of 15 in^3/sec was just about what it should

have been based on the water flow vs. pressure tests. Also, the LOX tank

ran dry much earlier than normal so that seems to indicate that the 15

in^3/sec is a believable number. I suppose it's possible

that on every prior run, there was a chunk of ice clogging up

some of the injector orifices or flowmeter. I'd really like to trust the

LOX flowmeter but I don't believe the data on any of the previous tests

with it. Without it though, you can't really trust computing the flow rate

based on the pressure because an orifice might be clogged with ice in that

situation too.

I thought I did a pretty good job drying out the LOX tank before the

runs but condensation collects around the top of the fill tube so maybe

some water drops down into the tank. Also, after each run, I clean out

the LOX flex hose between the ball valve and injector so it's possible

that there are a few drops of water left over in there. I blow hot air

from a heat gun through the flex hose for a few minutes and I figured

that would be good enough - maybe not.

The fuel flowmeter is reading spot on. After the last run of the

weekend, I drained the fuel tank and measured the remaining amount. I

compared the amount consumed vs. the integrated fuel flowmeter value and

it was very close. So, at least that is working.

As far as checking for clogged LOX injector orifices, the soot pattern

on the inside of the chamber after the run may yield some clues. I have

6 pairs of injector orifices and inside the chamber, I see 6 areas in a

pattern where the carbon residue has been scrubbed away from the walls and

you can see bare metal. So I guess the presence of that pattern would

indicate no orifices were clogged.

My leading theory of what is causing the low thrust on the

regen engine is poor mixing from the injector. The thrust and chamber

pressure of the uncooled engine seems to be fairly insensitive

to mixture ratio and was always in the range of 70-

80 lbf and 170-180 psia. The regen engine has similar geometry yet seems

to only put out 60-75 lbf and 135-160 psia. As I mentioned previously, I

went with the F-O-O-F split triplet design to try and keep the LOX away from

the walls in case of a clogged fuel orifice. I think most of the LOX is

just squirting straight out and reacting after it leaves the engine. I'm

not an expert in flame shape but the flame from the regen engine is

somewhat shorter than the flame from the uncooled engine with a similar mass

flow rate.

The next step is to build a new injector that uses 6 F-O unlike elements

and I'm going to put the LOX in the outermost holes, again to minimize the

effects of a clogged fuel jet. I will also continue to investigate the

issues with the LOX flowmeter to see if I can figure out what is going on

there.

There are some other interesting notes about the test this weekend. I

was seeing wildly fluctuating values in both flowmeters when I first hooked

up all the instrumentation. After much troubleshooting, I discovered the

TTL trigger line between the remote PXI chassis and the test control PC had

about 80 VAC riding on it. Both the PXI chassis and PC are plugged into the

same outlet but the data is transferred over a fiber optic cable so the only

ground is through the green wire on the extension cords. I ran a ground

wire between from the test stand to the PXI chassis and the problem went

away. I'm not sure why I didn't see this problem back in February. I also

didn't have any false starts with the ignitor this time. I taped the heck

out of the ignitor line into the end of the engine and it seemed to stay in

there long enough to get things started.

2007-03-23

Ran both the regen and

uncooled engines last month

at the new homestead test site.

The thrust from the regen engine was 74 lbf, a little better than last time but still

short from the design point of 100 lbf. I had flowmeters in both the fuel and oxidizer

lines so that allowed me to accurately determine the mixture ratio and mass flow.

Unfortunately, I only got one good run from the regen engine (just like last time)

and it was at the wrong mixture ratio.

Run 0 was a false start (see below) so Run 1 was the first real run. At the start of

Run 2, the flame looked terrible so assuming something was wrong, I hit the abort button.

A second or so later, the flame took a more normal shape so I think I was just too

quick to shut things down. I think what happened is that the coolant passages

were full of full from the first run so quite a bit of fuel burned outside the

chamber before the full load of LOX arrived. Then, on Run 3, it looked like

contamination showed up again (like last year's 2nd run) because the thrust and

chamber pressure were jumping all over the place. After tearing down the engine, my

suspicions were confirmed as I found lots of tiny particles in the injector

cooling passages. Apparently, the Grafoil flakes quite a bit when in contact

with the fuel so I need to find a better gasket solution.

As a result, I didn't get a chance to run the engine at the design mixture ratio

of 1.8. I've spent quite a bit of time analyzing the data so here's some of the

results.

-

Design mixture ratio = 1.8, actual = 1.5

-

Design chamber pressure = 200 psia, actual = 158 psia

-

Design Cf = 1.21, actual = 1.11

-

Design Isp = 217, actual = 156

-

Design c* = 5464 ft/s, actual = 4507 ft/s

The design Cf, Isp, and c* above were the values from Propep for RP-1/LOX

using the actual chamber pressure and mixture ratio. The values are better of

course when using the design chamber pressure and mixture ratio. I did notice

that the actual throat diameter was slightly larger than designed (0.736 inches

vs. 0.721 inches) so that will have a small effect. Also, for an actual chamber

pressure of 158 psia, the as-fabricated nozzle is slightly overexpanded which

also counts against you. Bottom line is that I really needed to run the engine

at the design point and I still didn't get to. However, I plan to run it again

in about a month so I'll have the opportunity to hit the design point more closely

next time.

If you look at the test photos, you may notice that I'm using a stainless steel

flex hose for the LOX line but an s-shaped copper tube for the fuel line. I

assumed there would be some error in the load cell measurement due to the rigid

copper line picking up some of the load but I didn't think it would be significant.

I checked the cal on the load cell

using a pulley with weights and found that the copper tube

picked up about 10% of the load. The 74 lbf above has been corrected by a factor

of 1.1 to account for this. Next time I'll use a flexible fuel hose.

I had problems with the ignitor popping out before the combustion could get

stabilized on two occasions this time. The arrival time of LOX vs. GOX in the

chamber appears to be related to how much pre-chill occurs during the LOX loading.

I was periodically cracking the LOX flow valve during tank fill to help chill

down the valve and flex hose. Ultimately I need either an ignitor that stays in

the chamber longer or a built-in ignitor of some sort.

A couple of days before the test, I performed some LOX flow tests to calculate

the discharge coefficient of the LOX orifices with the new flowmeter to help.

I've decided that I must be doing something wrong because the

results of the cold test aren't as close to the hot fire test as I would expect.

For example, one of the test points during the cold test showed a LOX

flow rate of 6.95 in^3/sec for a pressure differential of 114 psi.

On the hot fire, there was a flow rate of 7.07 in^3/sec

for a pressure differential of 143 psi. Based on the hot fire

pressure differential of 143 psi, I would have expected a value of about 7.8

in^3/sec. The ambient pressure was atmospheric (~14.7 psia) for the cold test

and 158 psia for the hot fire but I was under the impression that the effect of

back pressure was a smaller correction than that. I have a thermocouple installed

just downstream of the flowmeter and the LOX temp was -283 degF in both cases.

The test stand hardware had much more of a chill-down during the cold flow tests

so maybe the LOX wasn't 100% liquid during the hot-fire test?

For the last run of the day (Run 4), I ran the uncooled engine to see how a

different injector performs now that I have the flowmeters. Unfortunately,

I also miscalculated and ran it at a mixture ratio of about 1.5. The overall

mass flow was higher so that probably helped with the overall thrust of 81 lbf.

The measured Isp was 150.

Independent of the mixture ratio problems, I'm puzzled as to why the performance

of both engines is 25% low. I'm sure other LOX/kerosene engines in this thrust

class achieve a higher Isp so the challenge is to figure out what I'm doing wrong.

The only two variables I can think of practically changing is the injector

pattern and the chamber characteristic length (L*). I'm using an L* of 40

which is in the suggested range of 40-50 for a LOX/kerosene engine. I'm

contemplating making a few uncooled chambers with different L* to use with the

existing injector and running them during the next test.

Finally, the design of this web site is starting to get impractical so I need to

spend some time coming up with a new scheme to better organize the tests.

Putting all the news on one page probably isn't the best way to go.

2007-01-19

Things have finally settled down at work so I have some time to get ready

for the next test. I have the flowmeter, new valves, and all the plumbing

so I'm hoping to install those during the next week or two. I'm still

probably looking at about a month until the test though.

I had to make a signal conditioning box based on an LM-2917 to convert

the flowmeter output to a voltage for my data acquisition system.

A better and more accurate way would have been to run it to a counter input

on one of the DAQ boards but all my wiring infrastructure is geared toward

analog signals so I went with the F-V converter. Repeated cals of the

signal conditioner across multiple days show the slope and offset to be

within 1% which is good enough for me.

I'm starting to get antsy about developing the actual flight vehicle,

not just the engine. After this next set of tests, I'm probably going to

fabricate a new flight-worthy engine in the 250 lbf range and start

designing a vehicle around it. But, first I want to get a better handle

on the performance of my existing design. If the thrust and chamber

pressure values are still low during this next round of testing,

I'm going to try a more conventional F-O impinging injector instead of the

F-O-O-F split triplet I used for the existing regen engine. The key here

will be testing productivity though. Waiting a year between engine tests

isn't working out too well! I'm hoping for more like once a month.

And by popular demand... the drawings are back up, just without the

dimensions. Please don't ask for dimensioned versions.

|